The Factory's Quote is the Product

How instant quoting is reshaping machine shops — and where the real money is going.

Machine shops’ value prop has come unbundled

Shops historically offered a bundle of services to their customer around usually a single type of production process (eg laser cutting, bending, powder coating, etc). Since finding, evaluating, quoting, and scaling with a shop was very involved, customers were extremely sticky.

This is still the case for most large scale production. But the system didn’t work for everyone and a revolution has started. Small startups who just wanted to buy a 25 parts, hobbyists building project cars, and even engineers at big companies who needed parts the next day for their prototype were delayed, ignored, and overcharged by shops who could only process a few, highest priority requests at a time.

Companies serving these markets with the help of new technology have now started the irreversible unbundling of the machine shop ecosystem:

Shops used to sell engineering assistance aka “design for manufacturing” or “DFM” help.

Today, software tools (not even really using AI) can instantly help you with anything flat and many more complicated CNC parts.

Shops used to distinguish themselves on quality and delivering on the timeline promised. Labor skill between shops drove big differences in quality. It was hard to tell if a shop made good parts and delivered on time until you worked with them for awhile.

Today, shops use mostly (the same brands!) computer driven machines. Review sites make it easy to screen for a shop experienced in the type of parts you need and tell if they deliver on time

Shops used to require you to bring them a drawing and it took someone hours to tell you what it would cost.

Today, quoting software tells you immediately or after the sales rep reviews the work in 10 minutes. This has led to the rise of Instant quote powered “horizontally specialists” that produce sheet metal or another specific process at massive scale.

The result: bad shops have really suffered and the average quality in the industry is higher, but good shops are losing the stickiness and DFM differentiation that made them healthy businesses. Most time sensitive work goes to an instant quote marketplace or horizontal specialist. Most extremely cost conscious work goes to China1 or increasingly, a domestic metal service center.2

Shops’ next move

Prototype demand in American metalworking is exploding: supports for solar panels, lunar-lander brackets, and AI datacenter server racks. But shops still operating with the old model are struggling. Unable to compete with the scale of newcomers, but also providing the same services, shops have to pick a lane:

Double-down on one narrow step (horizontal focus) and become the lowest-cost, fastest producer of that step.

Climb the value ladder (vertical scope) and re-bundle around a set of physical steps (rather than services) your customers need: cutting, bending, finishing, assembly, even installation. Shift from selling parts to selling solutions.

Margin lives where complexity hides

Horizontal scale wins headlines, but vertical depth wins deposits. When every buyer can click “get quote,” the only defensible profit is the premium people pay to make their problems disappear. That premium pools where a shop owns the whole outcome. From first‐cut DFM tweaks to final torque spec, one PO means one neck to choke.

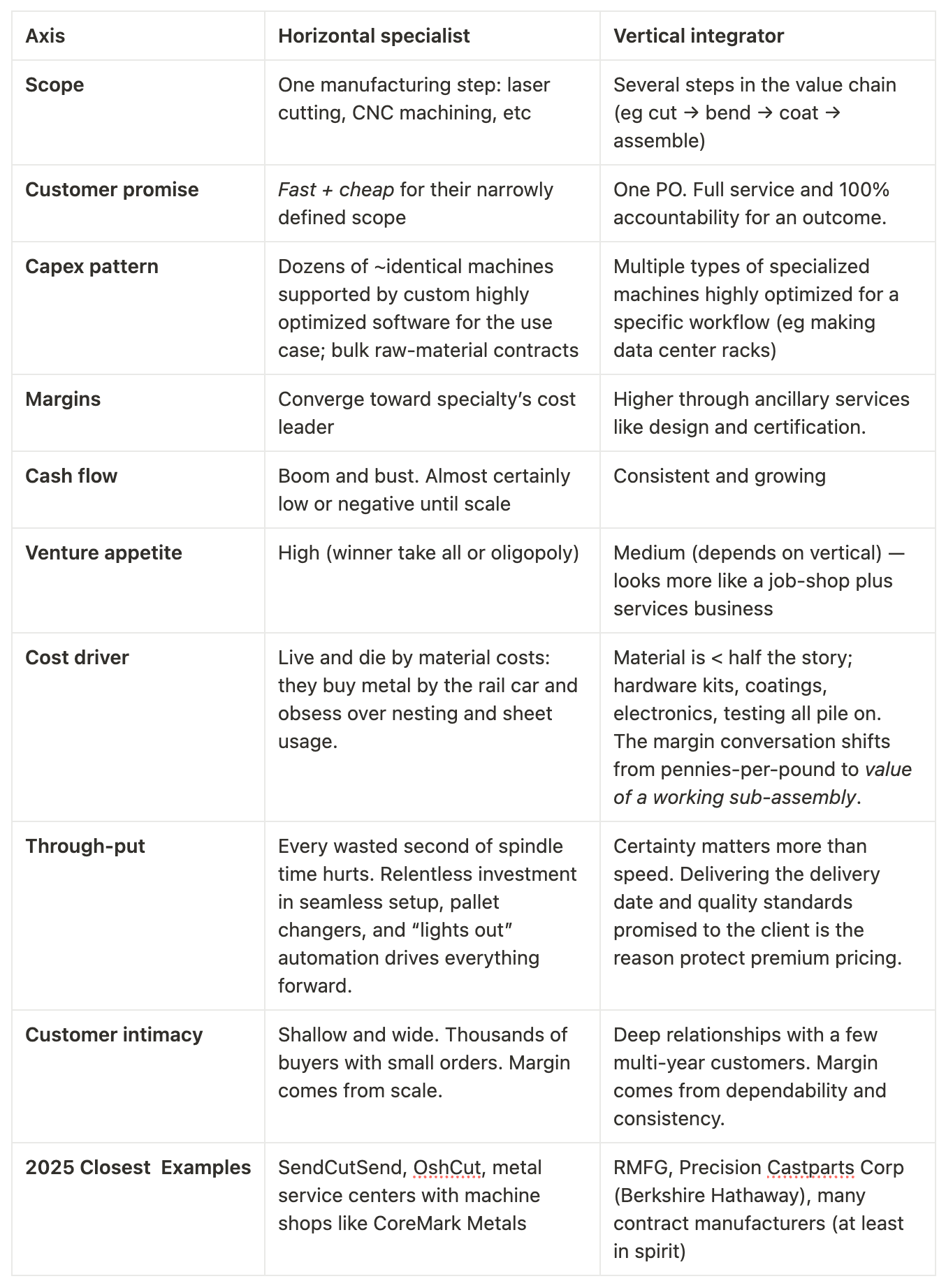

Horizontal specialists vs vertical integrators

On first look, it seems like these are two parts of a complimentary system:

Horizontal shops win when time and material efficiency are the customer’s top priorities.

Vertical shops win when uncertainty (complex parts that benefit from high DFM expertise, complex value-add processes, compliance) is the dominant pain and buyers will pay to transfer it off their plate.

While it’s clear that traditional shops are caught in the middle and will go out of business, if you dig a bit you’ll realize that those who who focus exclusively on horizontal scaling won’t build enduring businesses either.

Horizontal specialist: get big fast

While horizontal shops might look like the better path because of their scale, I expect their opportunity will look a lot more like an airline than a hyperscalers. Selling commodity parts is really hard!

The capex noose: constant investment with no pricing power

Just like airlines, horizontal specialists need intense ongoing capex to stay ahead. This hamster wheel of investment is coupled with low pricing power created by the instant quoting software they need to scale.

Expiring capacity: a prisoner’s dilemma

Shops are built on a queue of work. If there’s no work, machines and people sit losing money. Shops today commonly take unprofitable work from marketplaces like Xometry to recoup whatever costs they can when machines run idle. Horizontal shops will scale to saturate boom time markets before collapsing in downturns.

Data and process are not a moat

Large datasets of parts help get the companies off the ground but the advantage is logarithmic, not exponential. There are only so many way to make thing before your data is repetitive. Worse, a well funded challenger could effectively buy their way to this dataset (and market share) by subsidizing demand.

Geographic disadvantage

A facility can only grow so large before it saturates the area that it’s cost competitive to transport to. That area shrinks when a competitor opens (even a moderately inferior) facility closer to your customers.

Low barriers to entry

Competitors might be someone in their garage right next to your customer. You can start a machine shop with a few thousand dollars!

Instant quoting commodifies the market

Horizontal shops have initially scaled by offering instant quotations. It’s clearly a 10x customer experience that pulls demand to these first adopters. Industry veterans are skeptical, but they’ll be forced to adopt the technology as they hemorrhage customers.

As instant quoting increases, the friction to get quotes decreases, driving prices to converge around the lowest cost (probably VC subsidized) offering.

Vertical integration: get big smart

Vertically integrated companies might not initially be as interesting, but they’re probably the better business to own in the long run.

Relationships = pricing power

Shops historically differentiated themselves by providing DFM feedback. Vertical shops continue this with white glove service tailored for each customer. The success metric: how many shops replace their in house machine shop with your team.

When a competitor offers a cheaper quote, your customer isn’t choosing between parts, they’re choosing between people.

Deep data is a deep process moat

Verticals record fewer unique geometries, but accumulate process sequences: eg which powder spec plays nicely with which bus-bar plating or which torque spec cracks a particular composite insert.

This dataset is much deeper than a a horizontal shop’s so ages much better. The moment every sheet-laser giant knows what a 7075-T6 0.125-in pocket costs, price converges. Knowing that the pocket warps after hard-coat unless you tweak dwell time is harder to replicate.

Knowing the other 50 hard won lessons needed to make your customer’s satellite enclosure are a competitive advantage.

Transportation costs lessen and extend geographic range

Vertical shops save intermittent shipping costs but also ship items with a higher “product value density” than a horizontal shop, reducing the percent of total cost shipping eats and increasing the geographic range it makes sense to serve customers from.

How to win

The choice then, is stark:

Race to the bottom with ever-faster lasers and a balance sheet destined for consolidation or bankruptcy.

Climb the ladder and charge for certainty, stewardship, and the thousand hard earned tricks that turn steel coils into solutions

For builders, investors, and founders peering into American metalworking, the only enduring margin left is vertical. If you’re not getting paid to shoulder complexity, you’re volunteering to be the cheapest spindle in someone else’s supply chain.

They have someone making $4 / hour standing by 24/7 to reply to your messages so it might arrive faster than a US shop anyway.

These companies historically were the distribution layer between steel mills and machine shops. Their margins are slim and with instant quoting and increasingly computerized machines, they can view running a machine shop as a capex problem rather than a skill problem. With access to cheap metal and already operating at massive scale, I strongly suspect one of these companies will grow to be the largest horizontal specialist in the market.